Building a Custom Rifle: Step 1-Making a Plug (pattern)

In composite mould making, a plug (also called a pattern) is the master shape or template used to create the mould. It is an exact, full-scale model of the desired part or component. The plug is critical because the surface quality, dimensions, and geometry of the plug directly determine the quality of the final composite part.

Key roles of a plug, in composite mould making:

- Prototyping: The plug can be used as a prototype to test form and fit before the actual composite part is made.

- Master Template: The plug represents the exact dimensions and geometry of the final product.

- Surface Finish: The surface quality of the plug (smooth, textured, etc.) will transfer to the mould, which in turn transfers to the final composite part.

- Mould Construction: Once the plug is completed, materials like fiberglass or carbon fibre are laid over it to create a negative impression (the mould).

A well-made plug is crucial for ensuring the accuracy and consistency of the mould and, by extension, the final composite components.

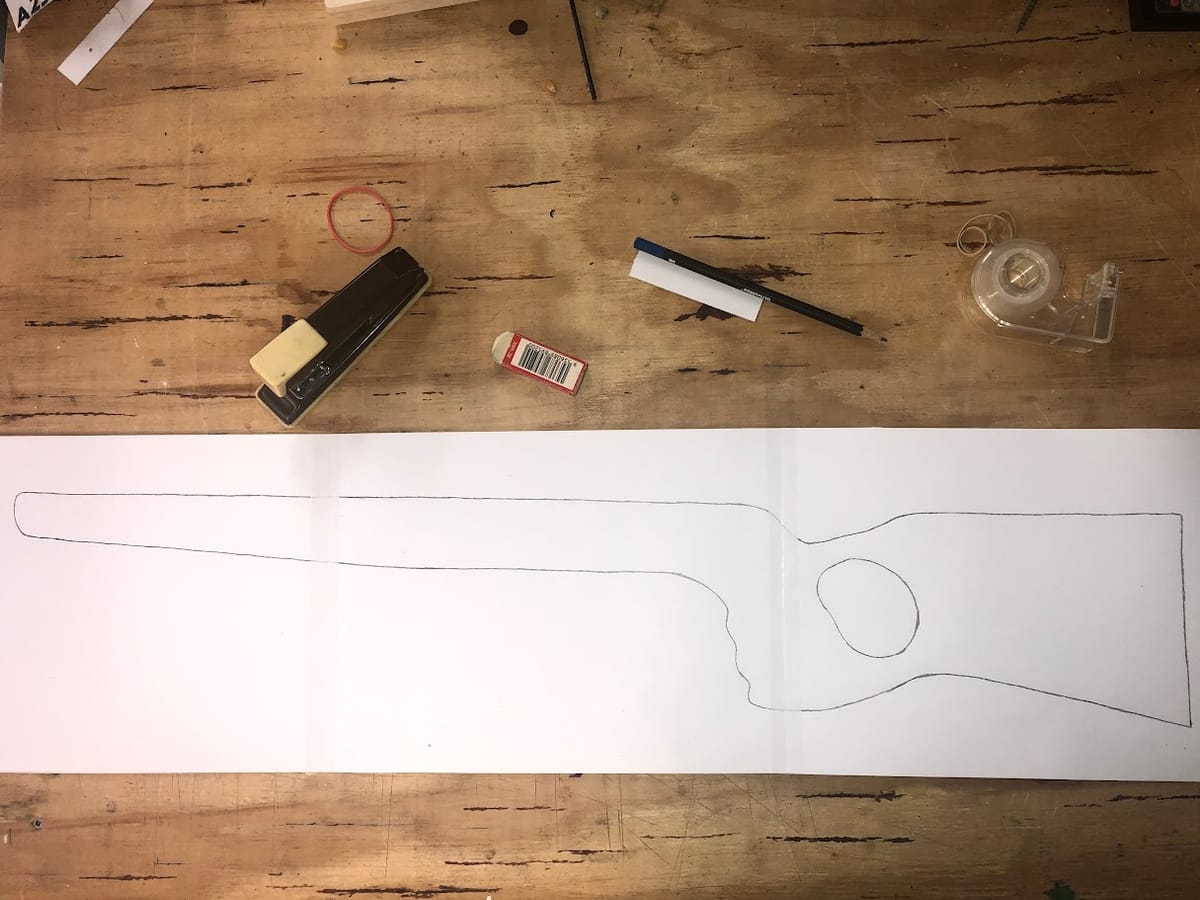

1. Creating the paper design

Start by defining the basic two-dimensional shape of the plug based on research, copying specific features from other similar items or adding features you wish to have as part of your design.

In my case, I based the design on Boyds At-One adjustable gun stock and a GRS Bifrost stock. Both stocks I owned and both with some features I like, but neither was a perfect fit on its own.

2. Transfer the paper design to the wood

I decided to use multiple plywood sheets to build my plug from because that allowed me to build up the plug in specific places where I want to have more material, like, for example, the ergonomic grip area.

Cut a paper template of the design, and use that to trace the design onto the wood.

Because my plug is not symmetrical, I mixed some blue paint with the glue so that I can see where the approximate centre line of the plug is (I will explain more about why this is helpful in the next blog post covering the mould making process)

The rest of the sheets of wood just get normal glue, but it is worthwhile to spend your time making sure the glue covers all areas of the sheets.

Combine all the glue-covered plywood sheets, and use clamps to keep everything in place. Leave the glue to dry based on the glue manufacturer's specifications.

3. Rough-cut the wooden plug shape

Cut the traced shape from the glued wood-pack, allowing for a small amount of margin (you can always take away, but it is more difficult to add material - although not impossible)

Outline the wanted shape on the top (or bottom) of the plug. The result will be a rough-cut shape of the custom rifle stock.

Add extra material in the areas where you wish you build the plug up, for example, in my case, where I want the grip to be off-centre to the right (I am a right-handed shooter)

Trace the recoil pad shape. This is not where the recoil pad will be mounted, but this serves as a good indicator to form the shape.

Then, after a lot of filing and sanding, you end up with a good representation of what the actual stock will look like. During this stage, the best way is to make small changes in the ergonomics and then test if it feels the way you want it to feel.

4. Fit the Barreled-action

Now it is a good time to fit the barrel and action. This specific stock is for a Howa 1500 action and barrel. This process involves cutting and hollowing out the inside of the stock so the action and barrel will fit snugly, and all the functions, such as the safety, will have the necessary space to operate as it was designed to do.

An important check is to make sure the trigger guard and magazine assembly fit correctly in the stock, and that it will feed the rounds smoothly from the magazine into the action.

With all of this done, we know the action and barrel fit into the plug-stock. The barrel has sufficient clearance to be free floating. The respective components (bolt, magazine release and safety) all work as they were intended to work.

5. Build the mechanisms

Machine and file the metal parts for the length of pull (LOP) mechanism. The "length of pull" (LOP) is the distance from a firearm's trigger to the rear of the buttstock, and it's a critical measurement for a proper gun fit. In a proper adjustable stock, you want to be able to change it depending on who is shooting and sometimes the type of shooting that will be done.

In this case, the mechanism uses pinch screws to lock it in place. The treading of the rods creates more grip for the pinch mechanism, so everything will stay in place even under higher recoil rifle setups.

With custom stocks, you end up with small customised parts. The mag release in this case required a slightly longer release lever. In the above picture, the black lever is the original that came from an old stock. The aluminium fabricated lever was made from a piece of 5mm aluminium flatbar (and some filing).

As with anything else, file a bit and test fit to make sure everything works as you expect it to work.

Every sport has its injuries - custom rifle building/gunsmithing is no different. While sanding the custom mag lever, holding on to the small metal part meant that my thumb developed a blister or two along the way. A small price to pay.

Fit the length of pull (LOP) mechanism with the recoil pad to make sure the amount of adjustment is sufficient. Where I found gaps, between where the wood and metal joined, I used standard automotive body putty to fill those areas. And yes, you guessed it - some more sanding and filing afterwards to make it smooth and nice looking.

6. Fit the mechanisms and continue the plug build

Adjustability is not just limited to the length of pull (LOP); the cheek rest height is just as important. This is what determines a perfect (and repeatable) fit to always have the best sight picture through the scope mounted on the rifle. This also future-proofs the stock by giving the flexibility to change scope types and scope heights in future.

The cheek rest mechanism is based on the same pinch lock mechanism as the length of pull (LOP). The size and amount of vertical adjustability are different, though.

7. Finishing touches

After all mechanisms have been fabricated, fitted and thoroughly tested, all mechanisms are disassembled and the stock is sprayed with an automotive filler coat.

The automotive filler is a thick filler paint that is sprayed in layers. After each layer, the stock is sanded with a fine sandpaper to remove all marks, dents and blemishes from the plug surface. As mentioned in the beginning, the plug is critical because the plug directly determines the quality of the final composite part, especially the surface quality.

The last part of the plug building process is to spray it with a gloss enamel paint. This protects the stock, gives it a smooth and shiny surface finish and helps with the release of the plug when it is used in the next step, when the mould is made.

Conclusion

Building the plug is a labour-intensive process. The more time that goes into this step, the better the final result will be.

The other reason why this takes a lot of time is that all the mechanisms (if you fabricate them all from scratch) involve a lot of precision and manual work. But the advantage is that at the end of this, you have a stock that could theoretically function as a real stock, but it is not as strong, durable or light as when it is machined from better quality wood or some composite material (like carbon fibre).